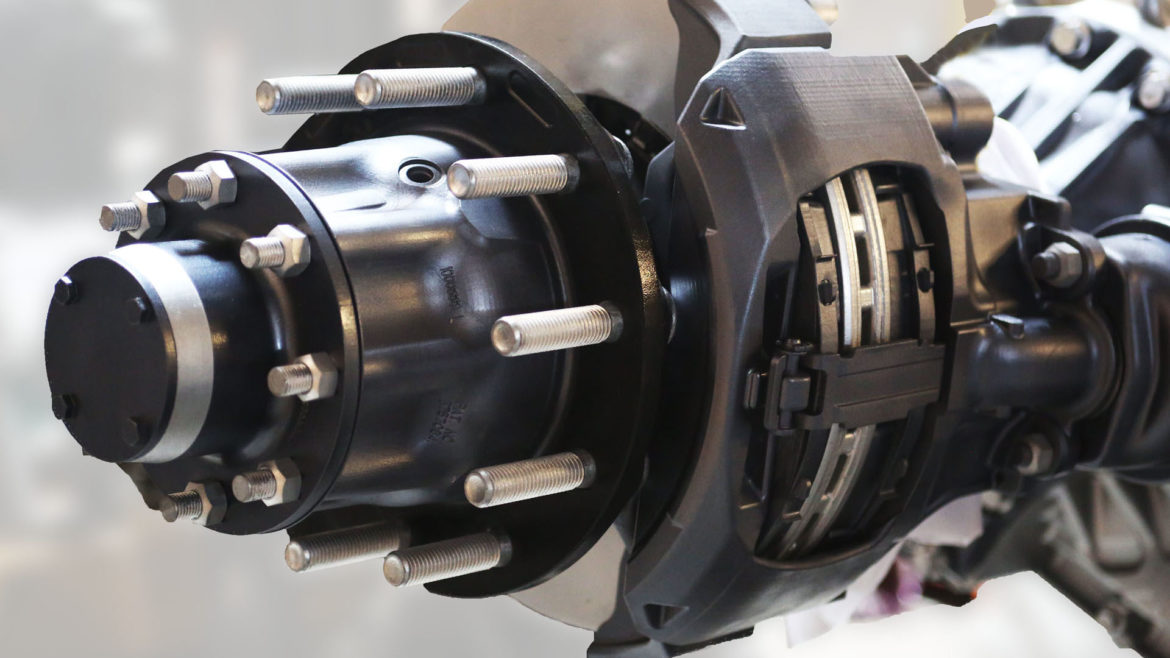

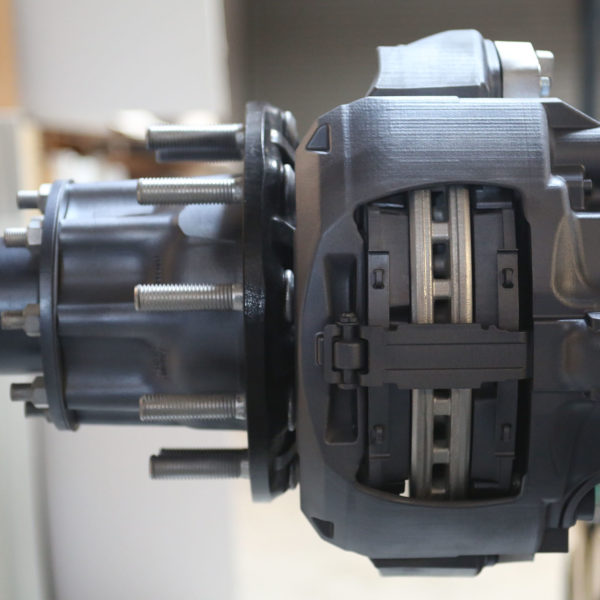

3D Print | Full-Scale Truck Axle

THE ART AND TECHNOLOGY

There are only a handful of 3D printers in the country that can deliver resolutions down to 50 microns. Our team has one. That’s resolution high enough to literally screw nuts onto threaded bolts! But that’s only half the story. We have the highest skilled CAD designers and fine-art painting staff in Las Vegas. Technology is important. But the realism is in the artistic finishes.

THE BENEFIT

This is so real it’s almost impossible to tell the difference. The actual truck axle weighs more than 2,500 pounds and costs over $100,000 to manufacture. What if you have trade shows throughout the year, all over the world? Or simultaneously? Wouldn’t you rather have 3 or more of these literal replicas to send to the show floor? Weighing less than 200 pounds each and far, far less expensive.

THE COST SAVINGS

Our customers tell us our 3D printed products can typically pay for themselves in only one use. And that’s purely based on the cost of shipping an actual product: freight, drayage and show handling. Not to mention tying up expensive inventory.

CURRENTLY, THIS IS THE LARGEST AND MOST DETAILED COMMERCIAL 3D PRINT PROJECT IN THE WORLD

Product Details

This axle was produced to full-scale and every detail represented. Hoses, wire housings, latches, screws and even serial numbers. The overall length was 9-feet but only weighed 190 pounds. The project was completed in under 30 days and, as with all of our projects, we fabricated a custom road case to ensure its safety each time it’s shipped. The case had rolling casters so it could be rolled from the receiving area to the show floor position. And only 2 people were needed to lift it onto a stand. Because it was real in every detail, we are currently building an AR experience so customers can literally ‘see inside’ how the transmission functions.